The History of Concrete

After 5,000 years, the legacy of concrete and its impact on the history of mankind is as enduring as the material itself.

The History of Concrete

The legacy of concrete is as enduring as the material itself. The following article discusses the 5,000 year history of concrete and how it has developed into Today's most frequently used material in the building industry.

Cement has been a naturally occurring substance for more than 12 million years and was used in rudimentary forms from about 3000 BC by the Egyptians, Chinese and Greeks. In man-made form, however, concrete was first developed by the Romans. Some time in the third century BC, they discovered that mixing volcanic ash with lime mortar, sand and gravel made a rock-hard substance similar to today's concrete. With the addition of animal fat, milk and blood, this substance was called pozzolan cement and was used to construct the Appian Way, the Coliseum and the Pantheon, as well as the Pont du Gard in Southern France.

After the fall of the Roman Empire, the quality of cementing materials diminished rapidly because most people simply were more interested in building with stone. The technique for making pozzolan cement was lost and didn't reappear again until midway through the Middle Ages. In 1414, the manuscripts of the Roman Pollio Vitruvius - which contained information about pozzolan cement - were discovered, thus reviving the interest in concrete. Fra Giocondo used pozzolan cement to build the pier of the Pont de Notre Dame in Paris in 1499, the first modern use of concrete.

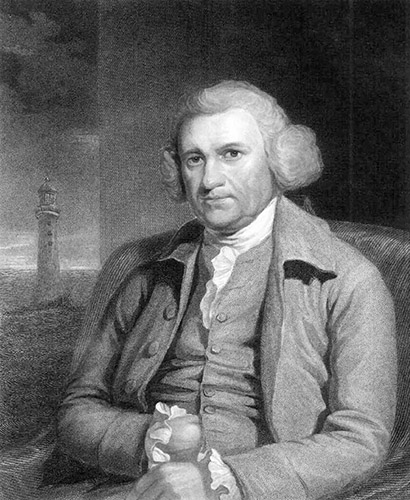

Concrete technology took a huge leap in the 1700s. John Smeaton was an English engineer looking for a building material that would not be adversely affected by water. He discovered in 1774 that quicklime made a harder cement. In 1793 he took that discovery another step forward when he realized that the calcinations of limestone that contained clay produced hydraulic lime, a lime that hardens under water. It was this material that was used in the historic rebuilding of the Eddystone Lighthouse in Cornwall, England.

Smeaton's work led to a more widespread use of concrete throughout England and further advances in technology. James Parker patented a natural hydraulic cement in 1796 that was made by calcinating pieces of pure limestone that contained clay. William Jessop used this technology to create the West India Dock in Great Britain, one of the first structures to use concrete on such a large scale.

From there, the popularity of concrete as a building material spread to France, where Louis Vicat developed an artificial hydraulic lime composed of synthetic limestone and clay in 1812. This technology was used in 1816 to build the world's first unreinforced concrete bridge in Souillac, France.

The 19th century saw rapid advances in concrete technology all over the world. One of the most important advancements took place in 1824 when an English bricklayer named Joseph Aspdin made an important discovery. He learned that burning finely ground chalk with divided clay in a lime kiln produced a cement that is much stronger than the previously used crushed limestone cement. This was called Portland cement and is still used in today's concrete production. Four years later, Portland cement was used in its first engineering application for filling a breach in the Thames Tunnel.

Another important technological advance came about in 1849 when the French gardener Joseph Monier began experimenting with ways to make a more durable flowerpot. He reinforced American William Wand's garden pots and tubs with iron mesh and the idea of iron reinforced concrete, or ferroconcrete, was born. Monier exhibited his creation at the Paris Exposition in 1867 and received a patent for it. Because reinforced concrete combines the tensile strength of steel with the compressional strength of concrete, it is able to withstand heavy loads and is commonly used in the building of many commercial structures even today.

After its inception, Portland cement became the focal point of concrete technology and many scientists and engineers turned their focus to it. One of the first patents for its production was issued to J. M. Mauder, Son & Co. in 1843. In 1845, Isaac Johnson claimed to have burned its raw materials to clinkering temperatures. However, it was American David O. Saylor who first demonstrated the importance of true clinkering in 1871 and he received the first American patent for Portland cement. J. Grant of England took Saylor's ideas a step forward by chemically analyzing the key ingredients of Portland cement and showing the importance of using the hardest, densest portions of the clinker.

In those days, the kilns used to make concrete were vertical and stationary, and were allowed to cool down after each use-a big waste of energy. A more efficient kiln was needed, and in 1885 an English engineer developed a kiln that was slightly tilted, horizontal and could be rotated. This was called the rotary kiln and allowed for better temperature control and more efficient mixing of materials. This resulted in a more consistent output of high quality concrete. By 1890, most kilns used in concrete production were rotary.

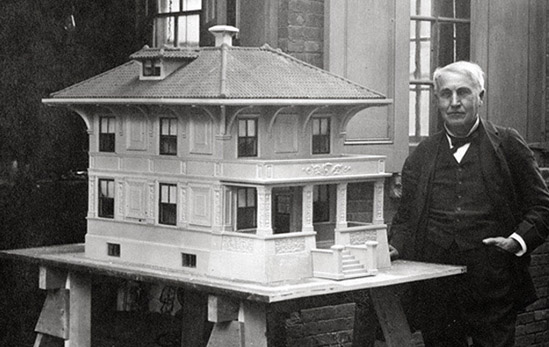

American inventor Thomas Edison advanced rotary kiln technology when he introduced the first long kiln in 1902 in his Edison Portland Cement Works in New Village, New Jersey. His kiln was 150 feet long, 70 feet longer than the kilns used at that time, and paved the way for today's kilns that are sometimes more than 500 feet long. Edison received a patent for his kiln in 1909. In 1908 Edison also built concrete homes in New Village, which are still standing today (pictured right).

The late 19th and early 20th centuries saw many firsts in concrete history, including:

- the first reinforced concrete bridge in 1889;

- the first American concrete street, placed by George Bartholomew in Bellefontaine, OH in 1891;

- the Ingalls Building, the first concrete high rise, in Cincinnati, OH in 1903;

- the first mile of rural pavement for automobiles in the U.S. (Wayne County, Michigan) in 1909.

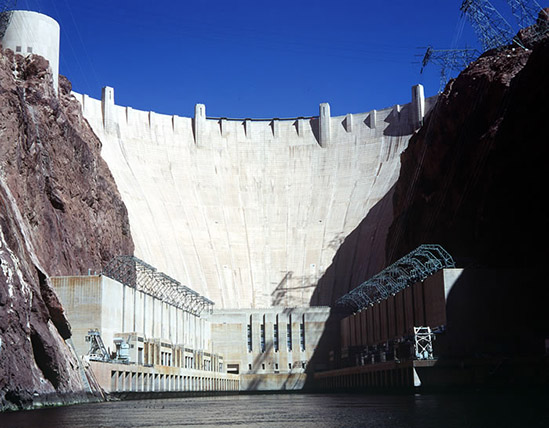

Other important concrete structures were built later in the 20th century and include the first major dams, the Grand Coulee Dam, built in 1933 and Hoover Dam, built in 1936; the first concrete domed sport structure, the Assembly Hall built at The University of Illinois in Urbana-Champaign in 1967; and the tallest reinforced concrete building in the world, built in Chicago, Illinois, in 1992.

Today concrete is the most frequently used material in the building industry and can be found everywhere in the world - in roads, houses, bridges, and many other structures. There are even concrete canoe and Frisbee competitions. Innovative concrete contractors are now constructing buildings with a new approach called tilt-up construction - read the article on tilt-up construction to learn more about this innovative approach for new building construction.

The legacy of concrete, 5,000 years in the making, is as enduring as the material itself. All around you is evidence of our technology and an important part of human history: concrete.